Chassis technology is a complicated interplay of

Comfort | Safety | Dynamics

Our chassis bushings meet highest demands regarding:

Suspension systems include various bushings. These bushings provide both maximum driving comfort and optimum vehicle dynamics.

We develop, produce & provide:

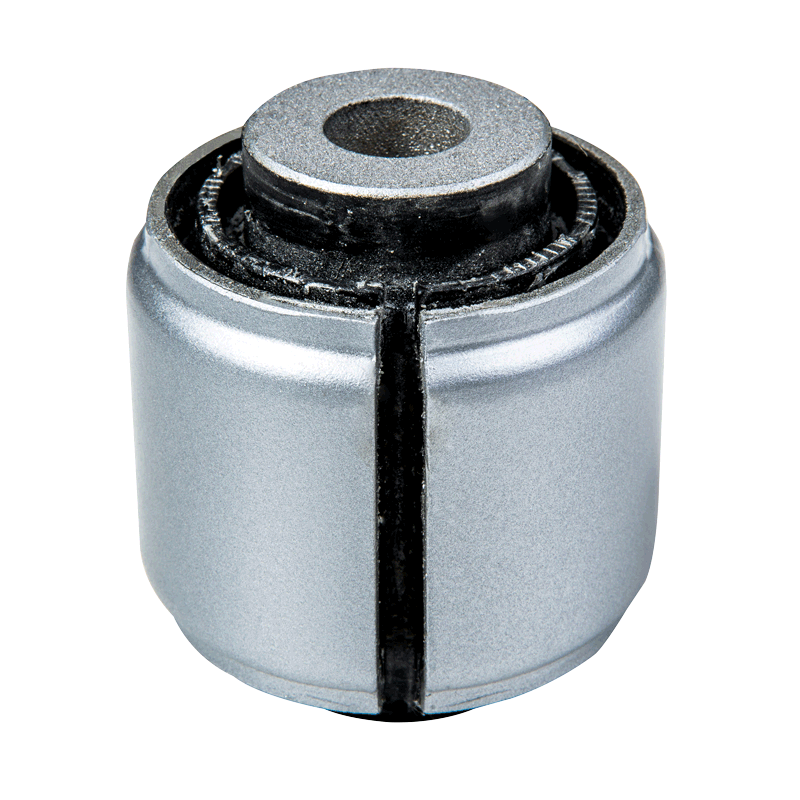

Slit bushings

The highly pre-tensioned slit bushing is one example of our innovative capacities. In contrast to swaged bushings, the Vorwerk Autotec slit bushing improves comfort | safety | dynamics of your car thanks to the smart utilization of physical properties. The clever construction and the profoundly thought out design contribute to a significant improvement of lifetime. Make use of these advantages – apply the Vorwerk Autotec slit bushing!

Hydro bushings

Ideal bushings must have contrasting properties in order to meet the high requirements on comfort and performance. Bushings exclusively made of rubber will after some time reach their physical limits in this respect. Therefore, we have committed ourselves to develop highly complex hydro bushings. Our hydro bushings combine the best of both worlds and provide considerably improved safety. We optimize performance and warrant comfort | safety | dynamics.

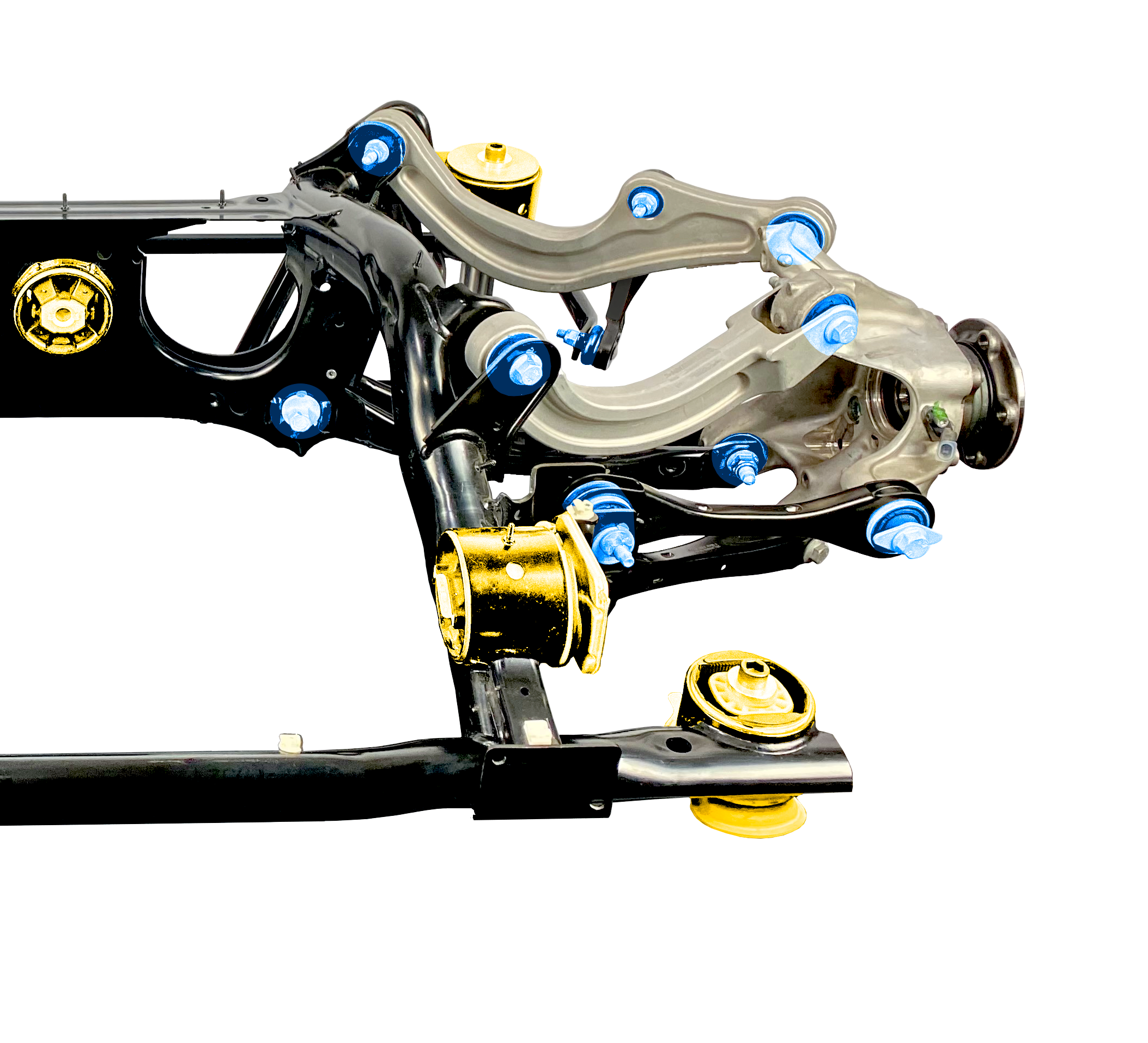

Subframe mounts

This bushing type is used as the central interface between the axle and body shell. Smart design requires optimized decoupling of noise and vibration and at the same time has to convey the sensation of driving precision. Thanks to our long-standing experience we are able to meet the challenge of optimizing vehicle dynamics while improving driving comfort. Our customers increase comfort | safety | dynamics by using Vorwerk Autotec subframe bushings.